Introduction

Concrete quality plays a crucial role in the strength and durability of any structure. One of the most important tests used on construction sites to assess concrete workability is the slump test. Understanding the slump value of concrete helps ensure proper placement, compaction, and long-term performance of concrete structures.

This comprehensive guide explains what slump value is, why it matters, types of slump, standard values, and common mistakes to avoid.

What Is Slump Value of Concrete?

The slump value of concrete is a measure of its workability or consistency in the fresh (plastic) state. It indicates how easily concrete can be mixed, transported, placed, and compacted without segregation.

The slump value is measured in millimeters (mm) using a standard slump cone test.

Why Slump Value Is Important in Construction

Proper slump value ensures:

Easy placement of concrete

Proper compaction without honeycombing

Uniform strength and durability

Reduced risk of segregation and bleeding

Incorrect slump can lead to poor concrete quality and structural issues.

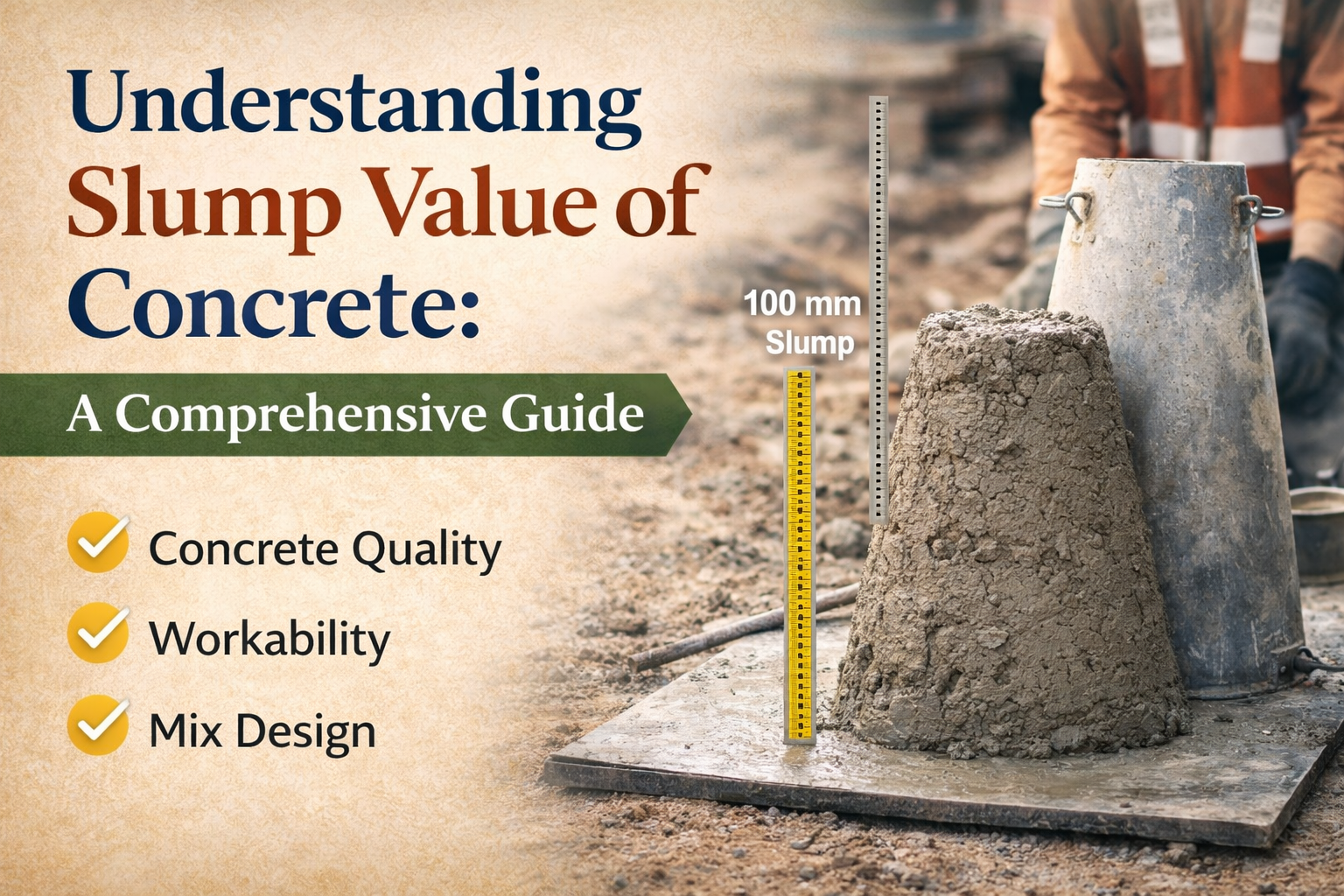

Slump Test – How It Is Conducted, Equipment Used for Slump Test

Slump cone (300 mm height)

Tamping rod

Base plate

Measuring scale

Slump Test Procedure

Place the slump cone on a flat, non-absorbent surface

Fill concrete in three equal layers

Compact each layer with 25 strokes

Lift the cone vertically upward

Measure the drop in concrete height

The difference between the original height and the slumped concrete is the slump value.

Types of Slump in Concrete

True Slump

Concrete settles uniformly

Indicates good cohesion

Acceptable and desirable result

Shear Slump

Concrete slips sideways

Indicates lack of cohesion

Mix should be redesigned

Collapse Slump

Concrete collapses completely

Indicates too much water

Not acceptable for structural work

Standard Slump Values for Different Works

| Type of Construction | Recommended Slump |

|---|---|

| Road Concrete | 20–30 mm |

| Mass Concrete (Foundations) | 25–50 mm |

| RCC Beams & Slabs | 75–100 mm |

| Columns & Pumped Concrete | 100–150 mm |

Selecting the correct slump value is critical for RCC construction quality.

Factors Affecting Slump Value of Concrete

Water-Cement Ratio

Higher water content increases slump but reduces strength.

Aggregate Size & Shape

Rounded aggregates increase workability compared to angular ones.

Cement Content

Higher cement content improves cohesion and slump stability.

Admixtures

Plasticizers and superplasticizers increase slump without adding extra water.

Common Mistakes Related to Slump Value

Adding excess water on-site to increase slump

Ignoring slump test results during concreting

Using the same slump value for all structural elements

Not accounting for weather conditions

These mistakes can severely impact concrete strength and durability.

Slump Value vs Concrete Strength

A higher slump does not mean stronger concrete. In fact:

Excessive slump often reduces compressive strength

Proper mix design balances workability and strength

Always follow mix design specifications approved by engineers.

Importance of Slump Test in Residential Construction

In residential projects like:

Foundations

Columns

Slabs

Staircases

Maintaining proper slump ensures long-lasting and crack-free structures. Reputed residential construction companies strictly monitor slump values on-site.

Conclusion

The slump value of concrete is a simple yet powerful indicator of concrete quality. Regular slump testing helps ensure proper workability, strength, and durability of concrete in all types of construction.

Understanding and controlling slump value is essential for achieving high-quality, safe, and reliable structures.

Need Expert Construction Support?

Choose a professional construction team that follows quality control practices, including slump testing, mix design compliance, and proper supervision.